To Control the process

Introducing the "ORIGINAL" PlasmERG Electronic Controller System

for the Plasmic Transition Process Engine.

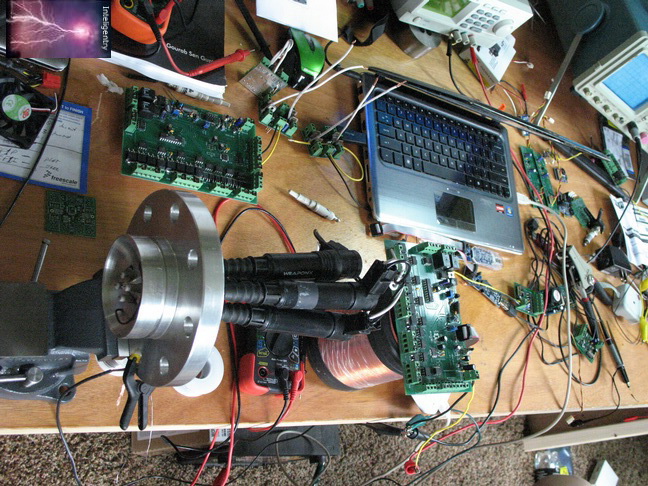

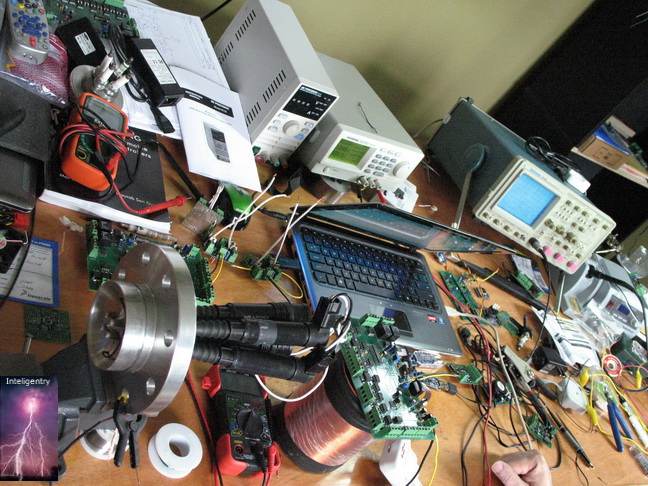

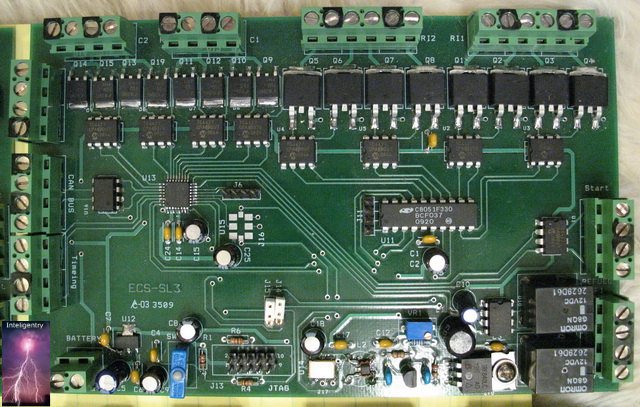

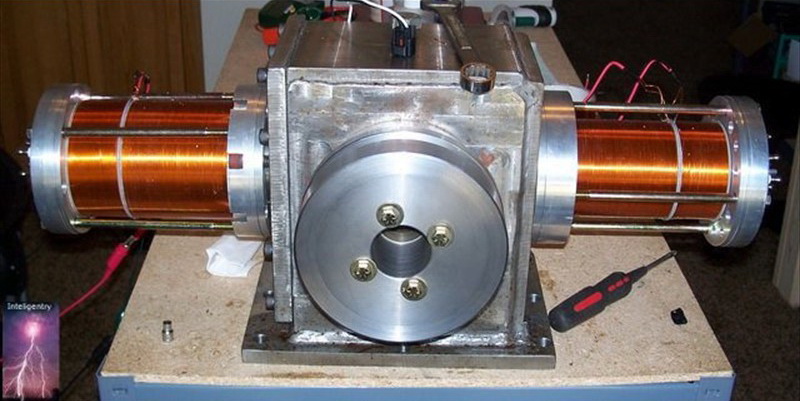

The Electronic Control System (ECS) used for the Phase 2 running PlasmERG engine.

============================

Plasmic Transition Development Group

and Control Systems Consulting, internationally

Copyrighted and newly Patent Pending

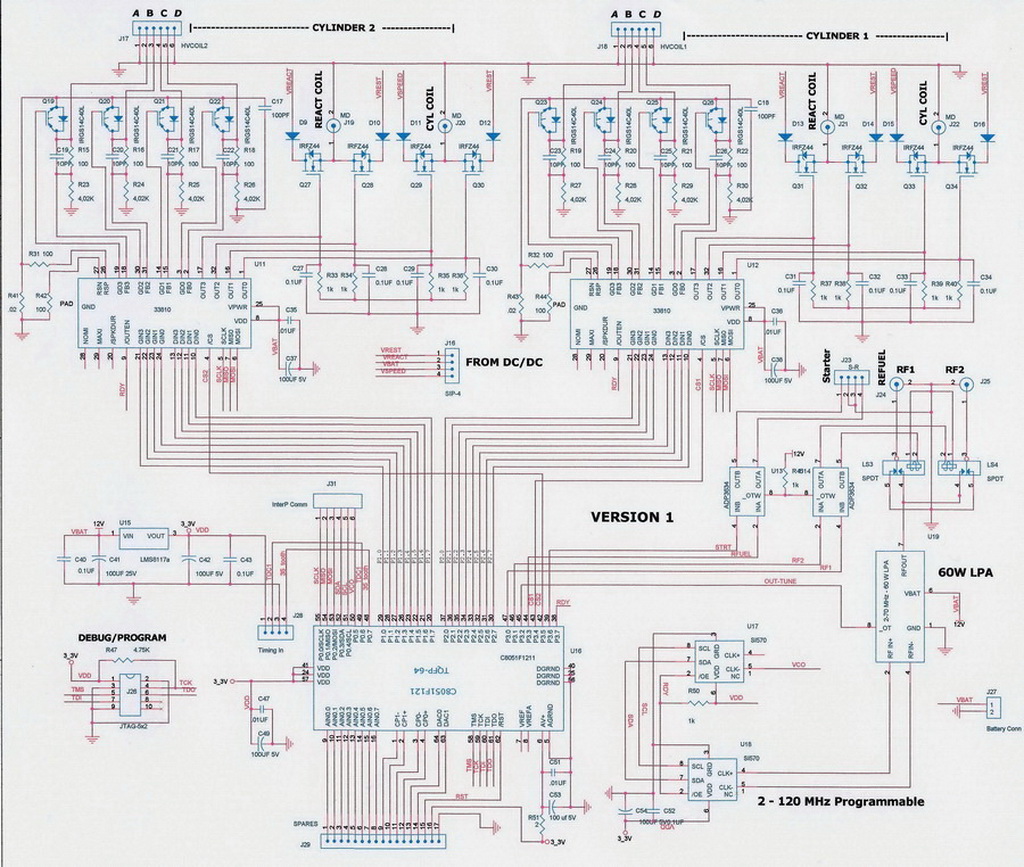

Electronic Control System (ECS)- electronic

controller System Overall Block Diagram. for a

Plasmic Transition Control System :

Taking what was learned by building and running

the PlasmERG (Iowa) Engine and what was needed to

accomplish that control system and to stretch

the very basic Papp International Control system, also

designed by John Rohner, resulted in a multiple

"embedded" Microprocessor single board controller

with all the basic elements on board.

This new board had all the coil voltage changes,

Timing input synchronization (to <1 degree),

RF frequency changes, RF Power Output Amplification,

RF switching, Electrode switching, Safety integration,

Plus control of Starter Motor and refuel pulse.

Complete operator control and interface.

The entire control system onto a single

board except for the variable voltage generators.

Best of all it worked and proved all theories.

=============================

The only real problem encountered was that the secondary Microprocessor that synced the electrodes got dropped from production. This had to be designed around and considering that a automotive Temp Range was needed anyway, and the 300 was no where near that it actually saved us time.

We picked up some smarts by replacing this part and that was going to be important later in the development cycle.

=======================================================================

Lets clear the air about a rumor!!!

There is some confusion being created and passed around by a nameless party, it

seems, about the progression of OUR controllers. We did not, in any way, duplicate anything

like the old 1982 John Rohner designed thing that made the old Papp International "Papp" engine work.

The first and simplest control circuit, that John Rohner designed,

was a modern technology mimic of the old Papp International "Certified" motor controller,

that John designed. It was based on his notes, drawings and a his timing MAP, also

presented in Papp Patents, as he corrected it. It was very simple, but.....

John did "simulate" his Ancient control circuit to verify it

met the published data about timings, would work within the constraints reported and

would perform within the very limited confines of operation as shown in the HISTORICAL videos.

BUT this Antique Controller design was

never meant to be used, as is very restrictive, cumbersome and inflexible.

But, STILL much better than Mechanical and Relay types.

Also, the Plasmic Transition Process system, has no need to

reverse coil windings, cross couple capacitors or any of the Mickey Mouse other things

from the Papp patent write up. These may be OK if the target is a

"perpetual motion" dream but useless in reality.

Our early simulations showed that the gains from all this added complexity was miniscule

in both power output or fuel retention and our tests since have proven this is true.

It's a messy thing to do and useless.